SPA brings your ideas to life by providing you with the support you need to create them.

The company is experienced in assisting and supporting customers during all the production stages of new thermoplastic components, studying the conceptual design, materials, equipment, and most appropriate process solutions.

Developing the product through collaboration with the client allows for fully customizing the part and the mould. In addition to being a true strong point, the company's design skills allow for the creation of highly innovative products in a reduced time. A greater guarantees of quality and reliability.

One of the competitive strong points of SPA lies in the design phase, where we respond to the customer’s requirements for the product, mould and the choice of material, whilst keeping a close eye on cost effectiveness and functionality.

FEM Analysis

FEM analysis carried out by state-of-the-art software applications allows us to test the structural elements of the product to be manufactured. Strain and stress analyses, torsion studies, deformation testing, etc. provide essential information for design verification prior to manufacture. With approval of the design and its simulated mechanical adequacy, the next stage is to prepare graphic and calculation reports that confirm the project’s compliance with current safety regulations.

Stress & Flow Analysis

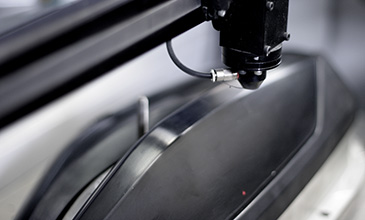

After the preparation of a computer image of the piece, proactive analysis of the necessary filling and the mould itself are performed so as to eliminate possible problems during the injection phase.

Three dimensional simulation based on mathematical models examines the points of filling and potential stress areas. The results of this analysis will impact subsequent mould design and manufacture stages particularly in terms of the points of injection and the thickness and type of material to be used.

Rapid Prototyping

Prototyping is not an exclusive requirement of the modern enterprise, but goes back to the days of pen and paper in order to refine design ideas and eliminate potentially costly errors.

SPA offers a rapid prototyping service which, during the design phase, focuses above all on a morphological analysis of the piece to be produced.

Rapid Tooling

SPA offers its customers the possibility of producing low cost, low volume moulds prior to the manufacture of the final mould.

Our mould shop can also produce moulds of one shape using metals with quick manufacturing times; the perfect cost effective solution for final pre-production testing.

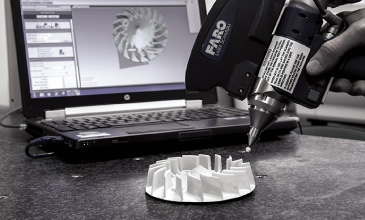

The design department is able to recreate the mathematical models of existing products in a very short time in order to return then to production.

The three-dimensional scanning of a sample allows for re-engineering the product to create a new, improved product that will be more efficient and more economically advantageous.

SPA is able to provide support throughout the production stages to those clients wishing to produce a specific object or component.

Experience acquired over the years enables SPA to manage the entire process of industrialization, from the development of specific design techniques to the formulation of proposals for how to improve a production process. Its integrated management of the production plant includes the configuration of process and product systems.