SPA has always engaged in seeking out an intelligent point of equilibrium between project economy and environmental impact.

The topics of sustainability are among the goals that SPA sets itself every day and affects all stages of the management of its buildings, activities, and production processes.

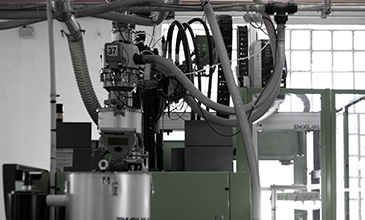

SPA is environmentally responsible: the exclusive use of closed circuit machines means zero emissions. All temperatures used in the moulding process are subject to rigorous control in order to eliminate the risk of noxious fumes.

SPA pays particular attention to its working environment. Its offices are built entirely according to green building practices with energy certification, as well as CasaClima Gold Nature certification.

A protocol that has made it possible to evaluate and certify the spaces created, not only in terms of energy efficiency, but also with respect to the environment and the health and well-being of our employees. In fact, in addition to meeting the efficiency index for building envelopes and that of CO2 emissions pre-set by the technical guidelines, on its inside, the building complies with precise requirements concerning air quality, natural lighting, and acoustic comfort.

A hanging garden was chosen for the roof covering, which, among its many advantages, increases the lifespan of the waterproofing system by providing protection against UV rays, intense temperature changes, hail, and deposits, while also improving protection against extreme temperatures.

For more information, visit the page dedicated to SPA on the CasaClima web Site:

VISIT THE SITE

SPA is a green, zero-emissions company: all production systems are closed-loop and release no emissions into the atmosphere.

Their temperature management systems allow for optimizing their energy consumption. In addition to contributing to the performance requested by our clients and to meeting product requirements, continuous research into the best raw materials available on the market contributes to the sustainability of the entire industrial project.

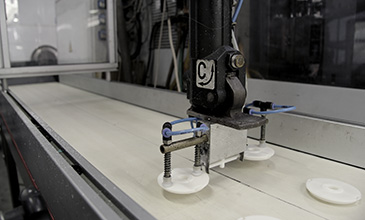

Using the most cutting-edge technologies available, SPA is able to contain the manufacturing costs of finished products while reducing their environmental impact by regenerating the production scraps.

The production facilities include special granulators for recycling scraps, when requested by the project specifications. The recycling and regeneration of production scraps takes place directly at the moulding machine.

SPA has the technology necessary for using plastic materials derived from external recycling processes.

Since 2011, it has manufactured an entire line of products from recycled plastics, transforming waste into production resources and contributing to minimizing the impact of plastics on the environment.

SPA operates in compliance with the quality standards set.

Manufacture of plastic products.

(Certificate no. AMER33725 - PDF format)