SPA is a highly-automated company, designed to handle all production levels, using the most modern means of production. The company boasts a full range of moulding machines equipped with all the technologies currently available on the market.

With a production capacity of over 100 million pieces per year, SPA is able to ensure quality and consistency throughout the production stages.

The machinery is equipped with automatic feed systems, and the moulders are equipped with robots for unloading, post-processing, and packaging activities. From small sets created using prototypical equipment to large-scale production created with definitive equipment, SPA turns its versatility into a winning tool.

SPA integrates a high level of automation into all stages of its injection moulding activities. Upstream this includes the automated management of material sent to machines in the mould shop.

Automated machines equipped with Cartesian robot technologies melt the plastic, inject it into a mould where, after cooling and hardening into the desired shape, it is separated from any waste material and placed on a conveyor belt for automatic packing. The packing process is also controlled by robot technology.

The company’s high level of automation guarantees highest product quality, efficient and effective production control and, consequently, competitive prices and rapid response times.

All temperatures used in the moulding process are subject to rigorous control in order to eliminate the risk of noxious fumes.

Machinery is equipped with dedicated granulators for in situ waste recycling where foreseen by project specifications to limit environmental impact. All waste wherever possible is immediately re-cycled in-house; in rare cases where this is not possible, non usable plastic waste is sent to legally recognised industrial waste processing firms.

The following is a list of the plastic moulding presses with the main characteristics.

You can also download the complete technical card

| Tons | Type | Injection Volume (cm3) | Press Max (bar) | Plan Dimensions (mm) |

|---|---|---|---|---|

| 800 | BMB 800 |

3920 |

1800 |

H 1400 x L 1350 |

| 700 | BMB 70Pi |

2894 |

1981 |

H 1370 x L 1370 |

| 550 | BMB 550 |

2860 |

1945 |

H 1195 x L 1095 |

| 380 | BMB 38Pi |

707 |

1812 |

H 1025 X L 945 |

| 300 | ENG 300 |

735 |

1480 |

H 1100 x L 700 |

| 200/250 | BMB 250/2200 NPM 220 220 ton. AR 570 C AR 570 S BI-IN |

1300 676,7 392 79 (O) - 38 (V) |

1700 1770 2000 2000 |

H 910 X L 840 H 830 X L 830 H 795 X L 795 H 795 X L 795 |

| 130/160 | AR 420 130 ton. AR470C 150 ton. AR470 150 ton. |

182 265 201 |

2120 2000 |

H 570 X L 570 H 650 X L 650 H 795 X L 795 |

| 110 | ENG VC BI-IN ENG VC BI-IN |

99 99 |

1451 1451 |

H 780 X L 740 H 780 X L 740 |

| 100 | AR 420 AR 420/C AR 420/C |

144 182 182 |

2120 2120 2120 |

H 570 X L 570 H 570 X L 570 H 570 X L 570 |

| 80 | AR 370C |

144 |

1820 |

H 570 X L 570 |

| 50/60 | AR 320 50 ton. AR 320C 50 ton. AR 320Ct2 50 ton. AR 320C 50 ton. AR 320Ct2 50 ton. AR 310C 50 ton. AR 320 50 ton. |

59 144 144 144 144 49 59 |

1820 1820 1820 1820 1820 1820 |

H 446 X L 446 H 446 X L 446 H 446 X L 446 H 446 X L 446 H 446 X L 446 H 446 X L 446 H 446 X L 446 |

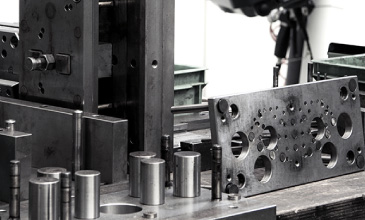

SPA has its own department specializing in the design and manufacture of moulds that avails itself of the most advanced technologies and top-quality steel. The latest simulation software (Moldflow®) and the most modern rapid tooling techniques allow the department to optimize projects in terms of productivity and of the quality of its finished products.

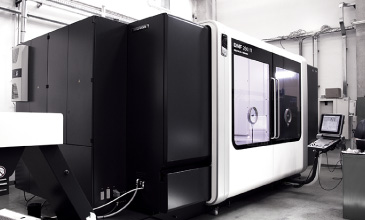

Equipped with state-of-the-art, 5-axis milling machines network-connected to a CAD-CAM system, the mould shop is able to create the product and the equipment required to produce it. It also features tooling equipment for the maintenance, modifications, and fine-tuning of all types of moulds.

The following is a list of the main equipment in the workshop for mold making.

You can also download the complete technical card

| Type | Model | X-axis | Y-axis | Z-axis | CNC |

|---|---|---|---|---|---|

| Cutter | DMG Mori mod. DMF 260/11 5X DMG Mori mod. DMC 75 V linear 5X GF MiKron VCE PRO 3X |

2600 886 800 |

1100 600 500 |

1000 600 540 |

Heidenhain Heidenhain Heidenhain |

All cutters are connected in the network, with post processor dedicated to interface with CAD-CAM system, Cimatron-relese 11/2014.

| Type | Model | Maker |

|---|---|---|

| Lathe | DMG mod. Nef 400 CNC | Simens |

| EDM | Plunge Plunge Wire Micro drilling |

Ona Ona Fanuc Vintes |

Various equipment (e. grinding, honing, milling machines etc ...) to complete the mold construction equipments.

Products are subjected to numerous, continuously evolving processing operations following their production. SPA has the know-how, the employees, and the equipment to deliver finished products that are ready for the market.

The company has established experience in all the stages of finishing and all the detailing required by the industrial project.

MACHINING

ASSEMBLY AND GLUING

ULTRASONIC WELDING

PAINTING

COMPONENT ASSEMBLY

LASER MARKING

PAD PRINTING

SCREEN PRINTING

An extensive business history, experience in the field, and continuous research into production processes and market demands have led to the creation of several SPA-owned patents.

These innovations demonstrate the company's ability to respond to technical difficulties encountered over the years and to successfully propose continual product improvements.